Business

Supporting tomorrow's electronics industry with our unique technology

Our main business is the development, manufacture, and sale of precious metal plating chemicals used for the contact and connection points of electronic components such as printed circuit boards (including packaged circuit boards), connectors, and lead frames. In particular, we provide comprehensive proposals and services, including process advice and after-sales support, and strive to develop, manufacture, and sell products closely tailored to user needs.

Since our establishment in July 1971, we have always focused on the electronics industry as our primary target, and have introduced gold, silver, and palladium plating chemicals for semiconductor packages and connectors to the market in line with the growth of the electronics industry. In particular, in product development, we have been developing our own proprietary technology system that does not rely on the introduction of technology from overseas, and we have been accumulating technology for many years.

Business model

Our company is often misunderstood as a venture company because of our small number of employees and our history of MBO, which resulted in our listing on the First Section of the Tokyo Stock Exchange. However, our company was founded in 1971 and celebrated its 50th anniversary in 2021.

During this time, we have built a business model that can generate high revenue without competing on the scale of human, material, and financial investment. We have narrowed down our target to "a niche field of the precious metal plating process in the cutting-edge electronic devices industry," and have realized a highly profitable product line by reducing the Cost of expensive precious metals, including software elements such as consulting solutions. This has enabled us to create a product lineup that is highly profitable and differentiated us from the general manufacturing industry, which is forced to pursue the merits of quantity.

1.Selection and Concentration

Deepen technology and anticipate needs by specializing in plating applications in the electronics field

2.Speed

Maintain a system that brings together the sales, engineering, manufacturing, and administrative departments' living rooms to speed up internal decision-making and customer response.

3.Formulation

We maintain a lightweight structure by limiting the manufacture of plating chemicals to formulation operations and outsourcing raw materials (confidentiality agreement).

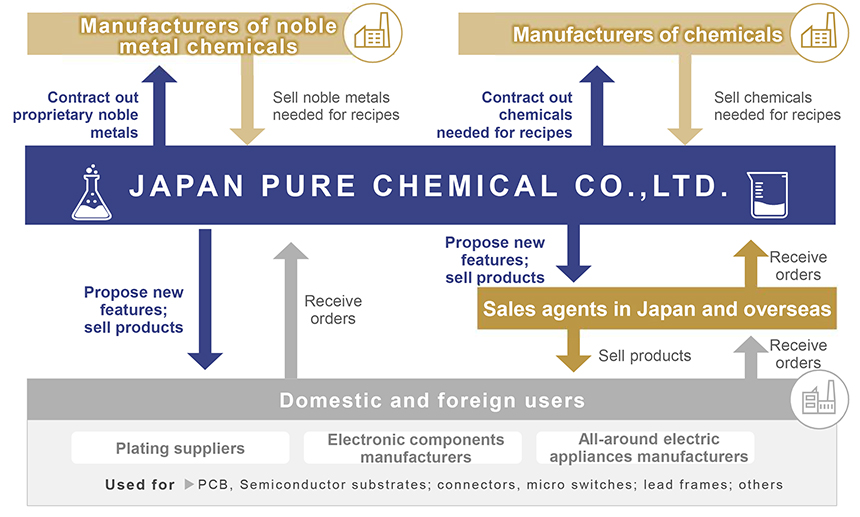

Business chart

Specializing in recipe development as fabless, development-oriented company with a few selected staffs

- Search for the best ingredients and formulations from the chemicals in circulation

- Plant synthesis and intermediate processing of each component are outsourced

Product Lineup ~Lineup Expansion and New Field Development ~