Basic Policy and Structure

The mission of our R&D department is to provide the electronics industry with the noble metal plating technology needed for surface mounting of state-of-the-art devices.

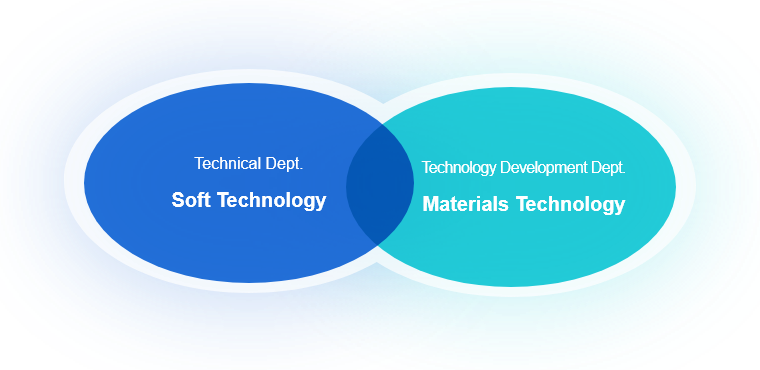

Customers for noble metal plating are rapidly globalizing, and in order to respond to this trend, it is necessary to promote our R&D activities in terms of both software and material technologies. Our basic policy for R&D is to respond to globalization by making full use of soft technologies, while at the same time fostering next-generation material technologies from a long-term perspective.

Soft technology is the technology to propose the best total process to customers by considering under what conditions and in what combination of front-end and back-end processes our existing plating chemicals should be used. The target electronic devices are diverse, and so are the customer's facilities. It is software technology that provides solutions that satisfy customers while taking these situations into consideration, and it is required to come up with solutions in a short period of time on how to fit our existing products into the customer's facilities.

Materials technology, on the other hand, involves the development of new chemicals to solve problems that cannot be handled by existing chemicals. The new chemicals are used in devices, go through the mounting process, and are eventually evaluated in a series of electronics devices (finished devices) before being certified as new products. Therefore, it may take several years of study from development to commercialization, requiring a long-term Forecast.

Especially for products for which problems cannot be solved without discovering new compounds, we must conduct environmental testing of new compounds, and although long-term R&D is inevitable, we consider it an essential condition for becoming a global fine chemical company.

Reference: Web site "Research and Development" (Top page>Products/Research and Development>Research and Development)

system

Our R&D department is divided into the Engineering Department and the Technology Development Department. The Engineering Department is mainly responsible for software technology, while the Technology Development Department is in charge of materials technology.

Major Issues in R&D Activities

Since our establishment, we have been supplying noble metal plating chemicals with the electronics industry as our primary target. In recent years, specifications that reduce the amount of gold used (gold saving) by using lower gold concentrations in plating solutions and thinner plated coatings are becoming more prevalent, and the main challenge is to meet these specifications while maintaining the physical properties of the plated coatings.

Even under such circumstances, we were the first in the industry to achieve cyanide-free electroless gold plating chemicals for MPU packages, providing new value in terms of both technical problem solving and environmentally conscious orientation.

Furthermore, in order to compensate for the decline in sales volume of noble metal plating chemicals due to gold saving, we are working to expand our accumulated noble metal plating technologies outside of the electronics industry and to apply them to plating technologies other than noble metals.

One of these is the development of battery materials. With the growing introduction of electric vehicles and renewable energy, there is a need for batteries that are cheaper, lighter, and last longer than conventional batteries. The charge-discharge reaction of batteries utilizes the same redox reaction (Redox reaction) as in plating. We have started to develop new technologies to contribute to solving the problems of battery materials with our Redox control technology cultivated through the development of plating chemicals.

In order to promote the development of these new technologies, it is necessary to develop a technical team with unique ideas that can compete with competing plating chemical manufacturers, whose technical staff is several times larger than ours. We will continue to hire and train highly qualified personnel who are willing to take on challenges in new fields, thereby raising the level of our technical team and strengthening our development capabilities. At the same time, we will seek optimal external collaboration in order to efficiently implement technological development that would be difficult for the Company to accomplish on its own.

Specifically, we will address the following issues

key issue

| (1) Environmental Issues Response |

- Plating technology that does not use hazardous substances (cyanide, lead)

- Reduction of grain-derived raw materials

- Reduction of plating waste>

|

| (2) Device support for new requests |

- Plating technology for high-speed communications network

- Plating technology for high-density mounting technology

- Plating technology for electrification of automobiles

|

| (3) Creation of new business areas |

- Development of technologies for battery materials such as electrolyte and electrodes

|

| (4) Efficiency |

- Utilization of experimental data

- Visualization of mechanisms

|

R&D Results

The results of research and development during the period under review are as follows

| (1) Nickel-free plating technology for high-speed communications network (DIG, EPIG) |

It is expected to be a final surface treatment process that can contribute to finer electronic circuits without the use of Ni plated coatings, which are generally applied in thicker layers. In this fiscal year, several customers have made progress in their evaluations of the process, and preparations are underway to optimize the entire process and commercialize the product.

|

| (2) Electroless gold plating technology for high-density packages

|

An environmentally friendly cyanide-free electroless gold plating solution for cutting-edge high-density semiconductor package substrates is now in mass production at a customer. Improvements are underway to further enhance performance.

|

| (3) Gold plating technology for semiconductor interconnections

|

Customer evaluations are underway for cyanide-free electrolytic gold plating solutions for leading-edge semiconductors. |

| (4) Battery materials

|

We exhibited at the 14th International Rechargeable Battery Expo held in March 2023 and presented our R&D results on electrolyte and metal nanomaterials for next-generation batteries. We have received inquiries from both domestic and overseas, and are now preparing for sample work.

|